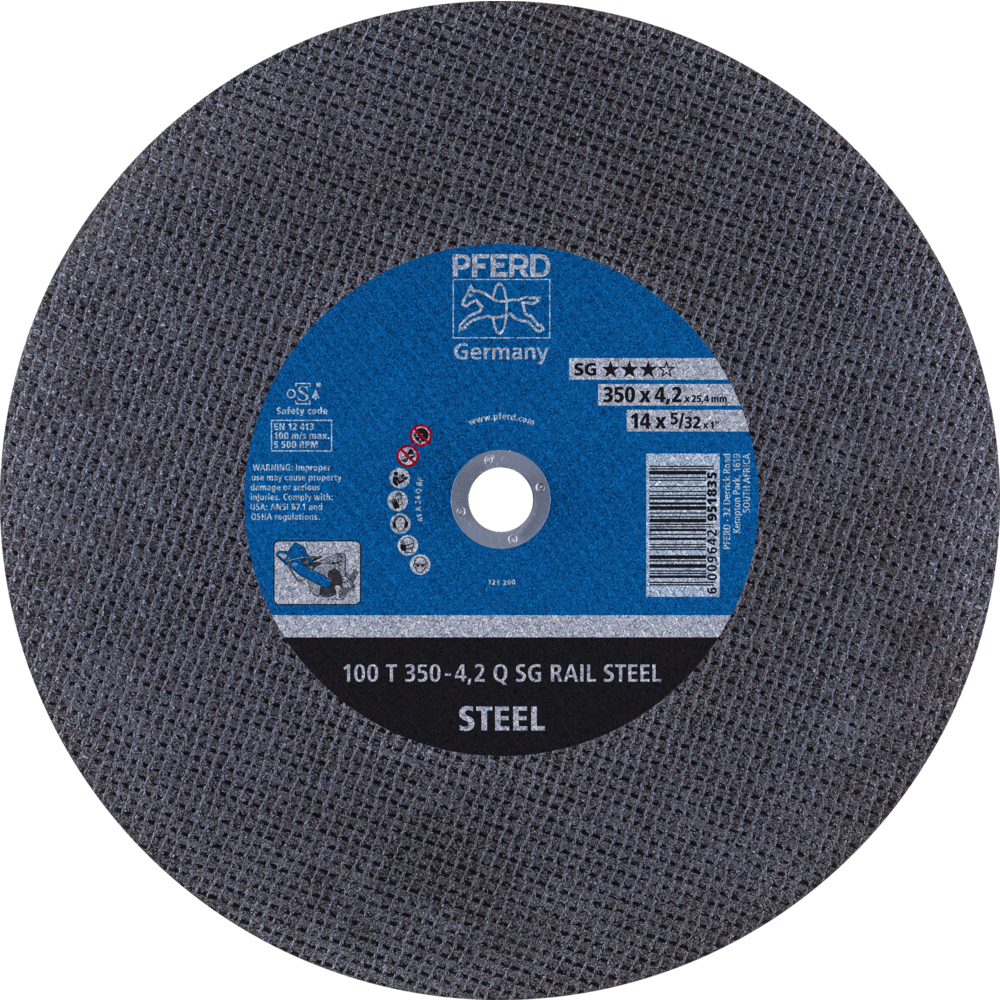

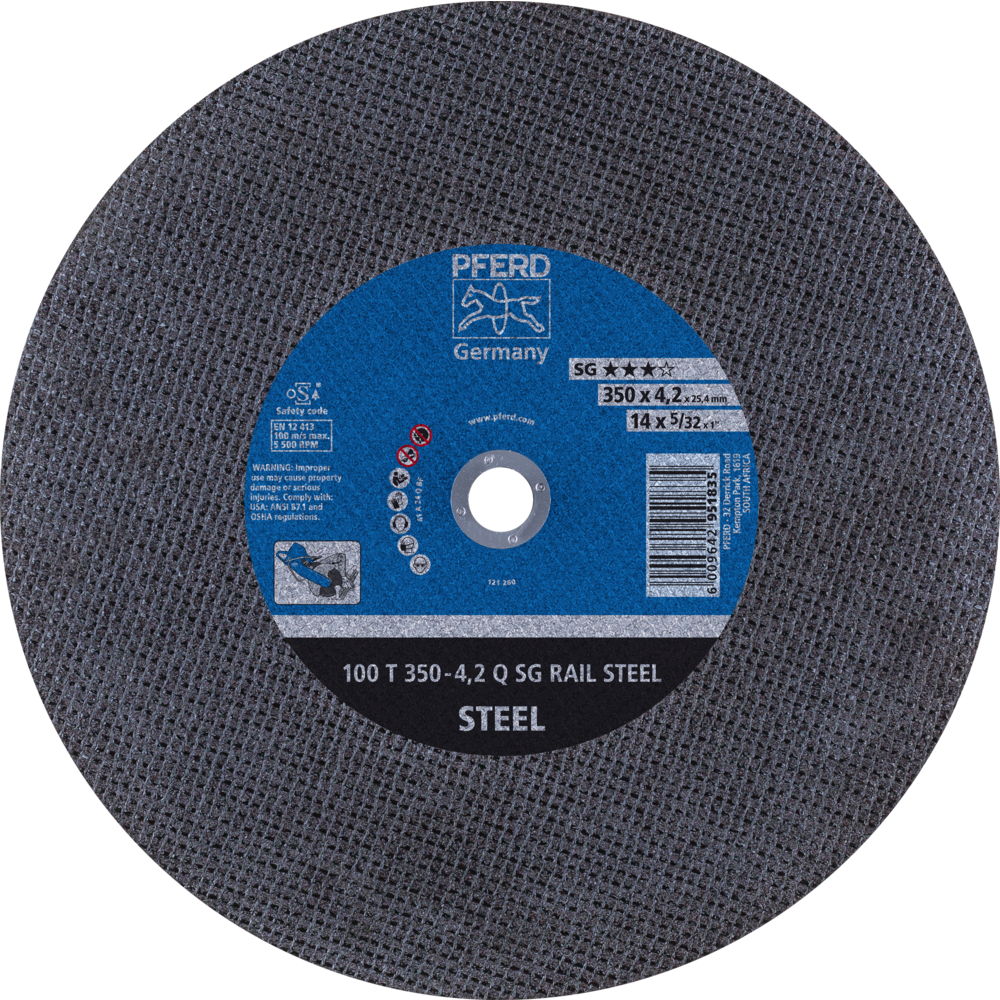

PFERD Rail Cut-off wheel - 350mm x 4.2mm x 25.4mm bore

Available for Delivery and Collection

Delivery Options:

- Door-to-door delivery via DSV Courier

- Delivery to DSV Locker

Collection Locations:

- PFERD Kempton Park Branch

- PFERD Pretoria Branch

- PFERD Durban Branch

- PFERD Cape Town Branch

- PFERD Gqeberha (Port Elizabeth)

Have a question? Ask an expert +27 11 230 4000 or email us sales@pferd.co.za

PFERD's range of stationary cutting discs are manufactured and evaluated in accordance with the strictest quality requirements. As a founding member of the Organisation for Safety of Abrasives, PFERD is committed to conform to tougher inspection requirements which even goes beyond international recognised EN 12413 safety standards.

The €œSG RAIL STEEL€ stationary cutting disc offer a very high cutting performance combined with an extended service life specifically designed for the cutting of rails. PFERD's focus on speed, safety, comfort, and overall superior cutting performance makes it the ideal cut-off wheel for on-site rail maintenance.

Advantages:

- Specifically designed and developed for the cutting of rails for the railway maintenance industry.

- Suitable for petrol driven rail cutting machines.

- Improved processing time due to high cutting performance.

- High economic efficiency.

- Minimum burr formation.

- Fast cutting action.

- Convenient and safe.

Specifications:

- Shape: Flat cutting disc (Type 41).

- Size: 350mm x 4,2mm (14 x 0.165)

- Bore: 25,4mm (1)

- 10x Cut-off Wheels in the box

Operating instruction:

- Observe the recommended rotational speed

- Maximum operating speed is: 100m/s or 5 500 RPM

- Only use stationary cut-off machines intended for use with the relevant tool.

- Ensure clamping flanges are the same size and consists of the same support area.

- Wheels supplied with paper blotters. Ensure blotters are used between abrasive wheel and clamping flanges as it assists with vibration reduction and reduces the risk of damaged caused by the clamping flanges.

- Avoid deburring workpieces on the sides of the abrasive wheel.

- Ensure correct and suitable personal protective equipment is worn while using the tool.

- Avoid material cross contamination.

For further operating instructions or product and safety information, please visit www.pferd.com or any of our social media pages.