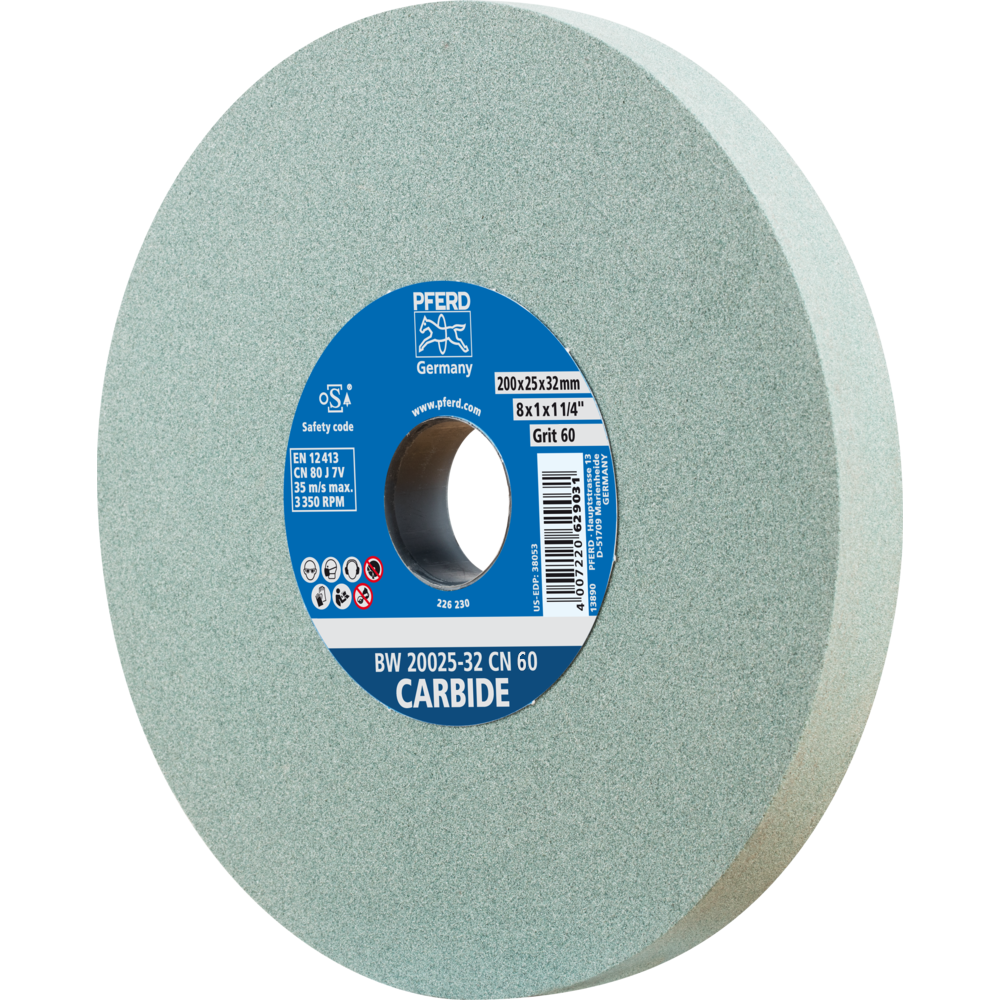

PFERD Bench Grinding Wheel 200 x 20 x 32 CARBIDE

Regular price

R 958.01

inc. VAT

Available for Delivery and Collection

Delivery Options:

- Door-to-door delivery via DSV Courier

- Delivery to DSV Locker

Collection Locations:

- PFERD Kempton Park Branch

- PFERD Pretoria Branch

- PFERD Durban Branch

- PFERD Cape Town Branch

- PFERD Gqeberha (Port Elizabeth)

Have a question? Ask an expert +27 11 230 4000 or email us sales@pferd.co.za

PFERD offers a range of high quality bench grinding wheels for working with a large variety of materials and for different applications such as deburring, working on edges as well as sharpening.

The PFERD CARBIDE type bench grinding wheels are particularly suited for use in application on hard materials such as sharpening of tungsten carbide tools. Suitable tungsten carbide, hardened and heat treated steels over 38 HRC and steel materials with a hardness of more than 54 HRC.

Advantages:

- Long service life

- High dimensional stability

- High abrasive performance

Specifications:

- 200mm Diameter x 20mm Width x 32mm Centre Bore

- Comes complete with a set of reducing bushes for the centre bore. Reduction from 32mm to 25mm, 20mm and 16mm possible.

- Green Silicone Carbide

- Grit Size : 60

Operating instruction:

- Observe the recommended rotational speed Maximum operating speed is: 35 m/s or 4 500 RPM

- Ensure correct and suitable personal protective equipment is worn while using the tool.

- Only use grinding machines that are intended for use with the relevant tool.

- Regular dressing of the bench grinding wheel is recommended to expose new fresh grain as well as to maintain an even grinding area. This will also extend the service life of the product.

- Maintain a maximum width between the wheel and the workpiece support of 3mm.

For further operating instructions or product information, please visit www.pferd.com or any of our social media pages.

The PFERD CARBIDE type bench grinding wheels are particularly suited for use in application on hard materials such as sharpening of tungsten carbide tools. Suitable tungsten carbide, hardened and heat treated steels over 38 HRC and steel materials with a hardness of more than 54 HRC.

Advantages:

- Long service life

- High dimensional stability

- High abrasive performance

Specifications:

- 200mm Diameter x 20mm Width x 32mm Centre Bore

- Comes complete with a set of reducing bushes for the centre bore. Reduction from 32mm to 25mm, 20mm and 16mm possible.

- Green Silicone Carbide

- Grit Size : 60

Operating instruction:

- Observe the recommended rotational speed Maximum operating speed is: 35 m/s or 4 500 RPM

- Ensure correct and suitable personal protective equipment is worn while using the tool.

- Only use grinding machines that are intended for use with the relevant tool.

- Regular dressing of the bench grinding wheel is recommended to expose new fresh grain as well as to maintain an even grinding area. This will also extend the service life of the product.

- Maintain a maximum width between the wheel and the workpiece support of 3mm.

For further operating instructions or product information, please visit www.pferd.com or any of our social media pages.